HEAT INSULATION G-4 FOAM

Cintailah Negara Kita, together we Minimize Energy Wastage & Reduces Global Warming

Copyright © GSE ONLINE SDN BHD ( 1116968-P ) ALL RIGHTS RESERVED

* Note : Users need to evaluate suitability on their industries use ( applications ) before placing order from us .

* Note : Users need to evaluate suitability on their industries use ( applications ) before placing order from us .

G4 FOAM -

Combination of XPE Foam Laminated with Aluminum Foil on top and bottom layer for Roof, Ceiling & Wall

Combination of XPE Foam Laminated with Aluminum Foil on top and bottom layer for Roof, Ceiling & Wall

Reduces Energy Wastage - Insulate Your House , Insulate Your Pocket & Improve Home Comfort

A) Product Name

G 4 FOAM ( XPE FOAM )

B) Raw Material

Combination of XPE Foam Laminated with Aluminum Foil on top and bottom layer

C) Purpose

Why Install A Better Quality Home Insulation?

There are many reasons for installing home insulation, and it can be one of the best investments a homeowner can make. Some of the main benefits of our home insulation can be seen below:

1) Lower Energy Costs - Reduce electricity usage, like air-con.

2) Improved Home Comfort - Insulation effectively improves your home's room temperatures.

3) Reduces Carbon Emissions- Recent research shows that thermal insulation could help reduce carbon emissions and save up to 350 million tonnes in waste by 2010. This is because insulation reduces the amount of wasted energy in your home.

Thermal insulation reduces the transfer of heat through building structures or envelopes. Thermal insulation not only reduces energy use and, therefore, CO2 emissions, but, in addition, the right insulation products also provide thermal comfort, acoustic insulation and fire protection.

4) Prevents Condensation Build-up - Condensation can be a massive problem within some homes, and home insulation can be used to resolve the issue. This is because it helps control airflow and stops the build-up of moisture in the air.

Why does XPE Insulation foam for industrial use turn into home roof insulation?

An innovative idea, effectiveness and characteristic of eco-friendly material composition. A new revolution for BETTER cost, energy-saving ( lower air-con consumption ) and " greener " house target.

Upgrading your insulation can significantly reduce energy costs and make your home a more comfortable living environment.

You probably don't think about insulation very much. It's that stuff between your walls and under your roof: out of sight and mind; however, if you understand how insulation works and the differences between insulating materials, you can make your house greener while saving a lot of green on your energy bills.

D) Scope

1) It can be installed on a roof, wall, floor, etc. It can resist over 80% of heat outside the building and protect the building from shock and sudden changes in the temperature.

The outer layer (aluminium foil) also has the advantages like reflecting light and heat and preventing the damage caused by ultraviolet radiation.

E) Characteristics

GS's Brand New Environmental-friendly Product In Malaysia is elastic, soft, light, and easy to install.

* Usage of GS Foam in industries:-

* Ducting/pipe Insulation ( either hot/cold piping )

1) Heat insulation and light inflecting in construction and protection for cold and hot water pipes.

2) Separation of the refrigerator; warm keeping for centre air-conditioner, refrigerator and other home appliances

3) Heat insulation, sound absorption and noise reduction for car, train, refrigerator car and laboratory; moisture-proof cushion for travelling

4) Packing for particular products and cold storage.

According to the INSULATION report, Our Sun can heat a roof to a temperature as hot as 65°C. Even light-coloured walls can be heated to as hot as 55 °C. In an uninsulated house, 40% of this heat can penetrate the ceiling alone.

5 ) Excellent weather resistant, environmental ( eco ) friendly and energy-saving character.

It is a high-quality material for warm-keeping and energy-saving, a strong opponent of anti-sweat cold and heat insulation. It insulates any heat media with a stable and low thermal conductivity.

It’s light in weight. It could absorb sound, reduce noise, and provide cushioning function.

6 ) Fireproof and smoke resistant

It’s water and leak-proof, anti-flaming ( flameproof means Anti-flame-SPREAD and the smoke density is very low, no hazardous materials produce ), and easy to be processed and installed. It’s durable in use and endurable to heat, cold, chemical reaction, etc.

7 ) Corrosion resistant

Excellent chemical resistance and anti-ageing.

Our GS Foam's advantages:-

A) Closed cell cross-linked structure: -

( Double Heat Protection )

(1) Reflect and

(2) Prevent condensation build-up &

( reduces ) Heat Penetration through the product.

* Reference Result Tested by US Firm based on 5mm Nominal Thickness.

(3) Total Insulation:-

R-Value: Above 15 based on one layer of 5mm Thickness unaffected by humidity,

R-Value: Above 21 based on two layers of 5mm Thickness unaffected by moisture.

( What is the R-value? )

A measure of the capacity of a material, such as insulation, to impede heat flow, with increasing values indicating a greater degree.

The thicker GS Foam, the higher the R-Value will be.

(4) Noise Reduction by 19dba impact noise for 5mm Thickness. ( IRAM 4063 )

(5) Flame spread index: 25 or Less ( E84-10 )

(6) Smoke Developed Index: 45 or Less ( E84-10 )

(7) Perm Rating : Less than 0.1 ( class 1 vapour barrier ) ASTM E-96

Our GS foam of heat insulation OFFERS 2 layers of aluminium foil as XPE Foam protection. ( Reduce direct heat penetration & UV protection )

Our GS Foam consists of

Layer 1 ) Aluminium foil ( top layer ) -- protection layer.

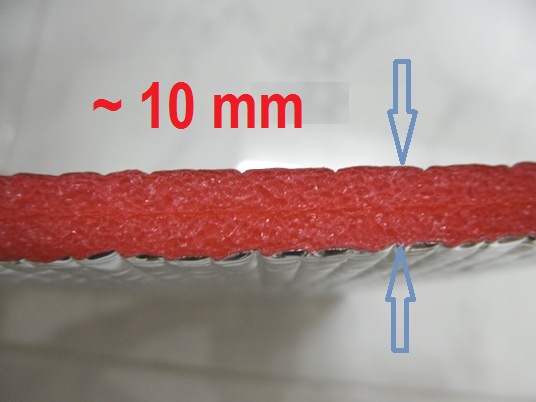

Layer 2 ) XPE ( middle layer ) -- ~ 10 mm thickness .

Layer 3 ) Aluminium Foil ( bottom layer ) -- protection layer.

With volume density up to 28kg/m³, heat insulates performance higher than the Aluminium bubble foil without XPE foam in the market, overall EXTRUDED thickness as THICK as 10 mm.

It stops > 95% radiant heat and bulk to protect against convection heat and multi-layers of obstruction material. It is an environment-friendly product with good heat preservation and insulation properties.

Each product layer has an exemplary function on abrasion and tearing resistance.

The middle layer ( XPE Foam ) shows strong ability in moisture barrier, oxygen reduction and sound insulation.

Application :

1. Heat insulation and light inflecting in construction are appropriate for buildings, factories and homes.

* Recommended for temperature : (-ve ) - 20 °C to (+ve ) + 80 °C

( based on a single layer )

Our GS Foam Characteristic:-

1) Our GS Foam is a cross-linked, extruded, expanded cellular polyethene foam.

2) GS Foam has innumerable tiny closed cells with an excellent uniform structure. Our GS Foam offers an overall thickness of ~ 10 mm extruded thickness.

3) GS Foam is a very versatile and unique product by its valuable

characteristics.

Salient XPE ( middle layer ) Features:-

1) Cushioning and shock absorption property

2) Thermal insulation

3) Flexibility

4) Resilience

5) Easy to fabricate

6) Water/moisture resistance

7) Non-CFC

8) Non-toxic, hygienic and fungal resistant

9) Lightweight

Comparison of our GS Foam with bubble foil and fibreglass wool in the market

1) GS FOAM's " COMPACTNESS" and heat resistant character as a heat insulation material are significantly more effective than traditional Aluminium PE bubble foil in the same size, dimension, and thickness.

2) Some Fibreglass wool may irritate human skin when in contact, and the majority is a non-flameproof / non-fire retardant material.

Things to consider before choosing a QUALITY heat insulation material:-

1) Product Density & Thickness

( Technically, higher density and thickness offer better insulation performance )

2) Ozone ( Eco Friendly ) & User Friendly -- GREEN products.

3) Maintenance FREE.

4) Product characteristic.

5) Application.

6) Long Lasting.

How to Install Roof Insulation ( Propose for New Build Home ) --

1. Starting at one end of the roofing framework, measure the length across the trusses, adding enough to allow hang at both ends. Cut the first piece and lay it in place.

2. Pull tight from both ends and attach to trusses and purlins using self-tapping screws, washers, or pressure-sensitive aluminium tape.

3. Cut the second length, laying parallel to the first. Make sure to butt or slightly overlap edges. Staple / Tape ALL seams. Fasten with self-tapping screws or aluminium foil tape, sufficient to hold in place.

4. Roof sheeting can be applied conventionally as soon as sufficient insulation is in place to accommodate sheeting width. When welding the roof deck to the trusses and purlins. Minimal effect on the weld.

5. An alternative taping approach combines it with installing the roof decking. After the first insulation piece is installed, fold the open end back over the roof deck. Butt the second length of insulation to the edge and tape. Then fold the second piece back over the roof trusses and continue to install the deck.

* You may also place on top of ceiling or plaster ceiling ( Minimize Manpower Cost )

GS Foam Wall Insulation

( Seek your Interior Designer / Construction Contractor's opinion for an iconic image of your wish )

People tend to have less concern about heat transfer on walls.

However, walls are a thermal mass that can store heat and slowly gain into the building for several hours after sunset. Consequently, air conditioners have to work harder to reduce the ambient temperature. This resulted in you having to pay more for cooling down the wall. With the iconic background, installing GS Foam and board COVER ( like Cement board / Gypsum board ) may significantly reduce heat transmission.

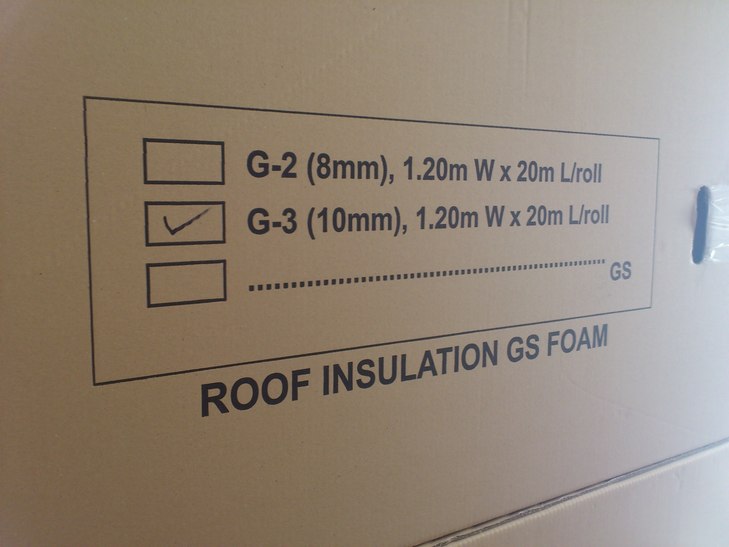

F) Specifications

1) Model No.: G4 FOAM

2) Standard Dimension ( Packaging ) :

Product Dimension :-

~ 10 mm ( Thickness ) x 1.20 meters ( Width ) x 20 meters ( Length ) / roll

= 24 m ² x 10.76 ( m ² convert to ft ² )

= approximately ~ 258.24 ft ² / roll

Product Size : Diameter ~530mm x 1200 mm Length per roll ( ~ 15 kgs / roll )

G 4 Foam

( XPE FOAM )

( XPE FOAM )

One Product , One solution for all - Cold, Heat and Water Condensation =

Reflective Insulation + Radiant barrier + Vapor Barrier

Reflective Insulation + Radiant barrier + Vapor Barrier

Model No.: G4 FOAM