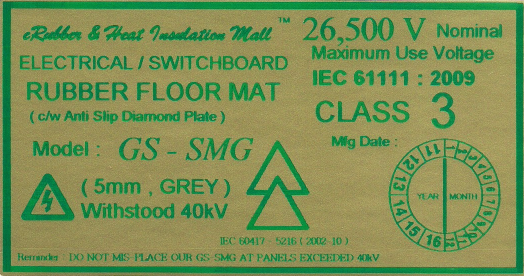

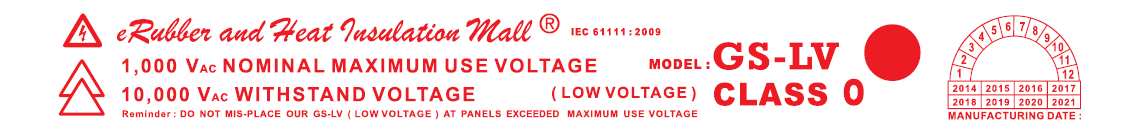

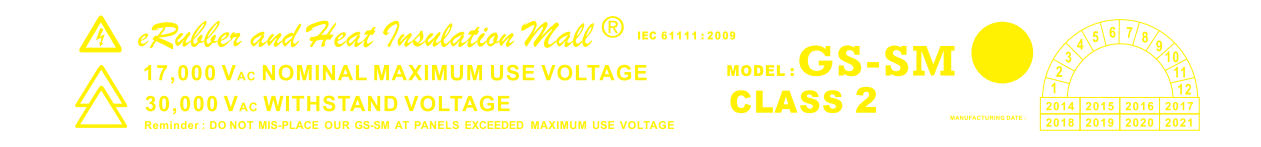

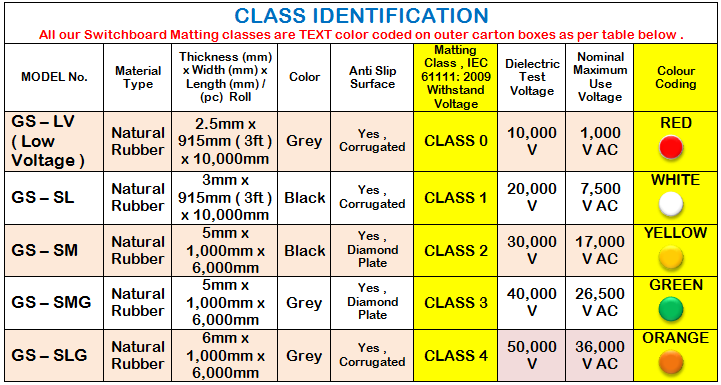

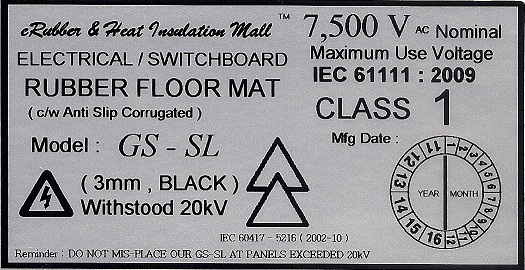

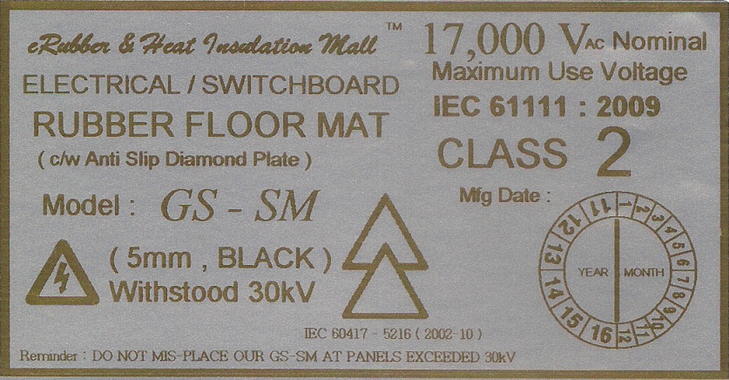

Indication Label : At Bottom of Rubber Mats

Non Conductive Switchboard Mat / Dielectric / High Voltage Insulation Rubber Mat Malaysia

-- with Anti Slip ( Corrugated / Diamond Plate ) Top Surface

Copyright © GSE ONLINE SDN BHD ( 1116968-P ) ALL RIGHTS RESERVED

This webpage is designed to guide potential and existing users wishing to conform to the new EU/UK requirements for the supply and use of matting with electrical safety and resistance characteristics and make the correct choice from the explanations and details listed below.

A) Which product is the correct Electrical Insulating Matting for protection against electric shock risk?

BS EN 61111:2009 is the latest standard for electrical insulating matting in providing electrical protection.

B) International Withdrawal of BS921:1976?

This old standard is being withdrawn on 1st Jan 2013 ( Standard number, BS 921: 1976, Specification: Rubber mats for electrical purposes, status: WITHDRAWN ) as it conflicts with IEC61111:2009.

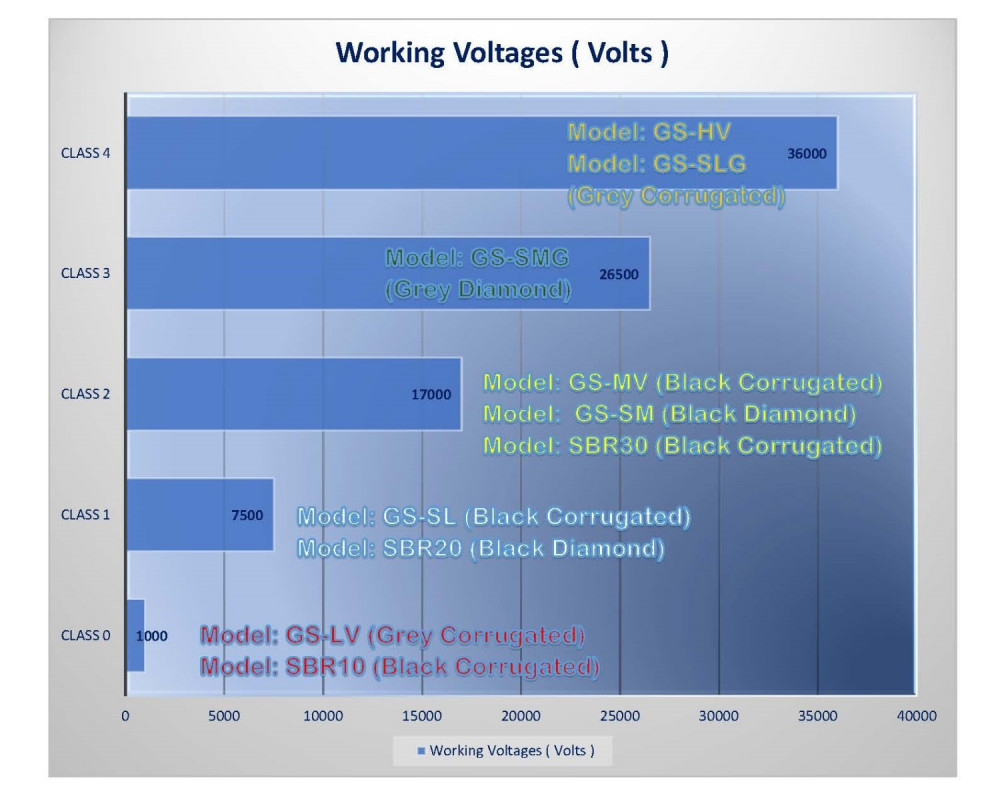

The direct Electrical Insulating Matting to replace BS921 is class 0 IEC 61111:2009 for working up to 1kV AC.

For higher voltage, you may select higher classes 1, 2, 3 or 4 according to the voltage resistance required.

C) Quality Assurance

Our Switchboard Mattings are backed with a detailed test certificate & RoHS compliant from an independently accredited Malaysia Test Facility.

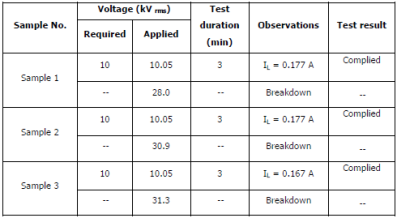

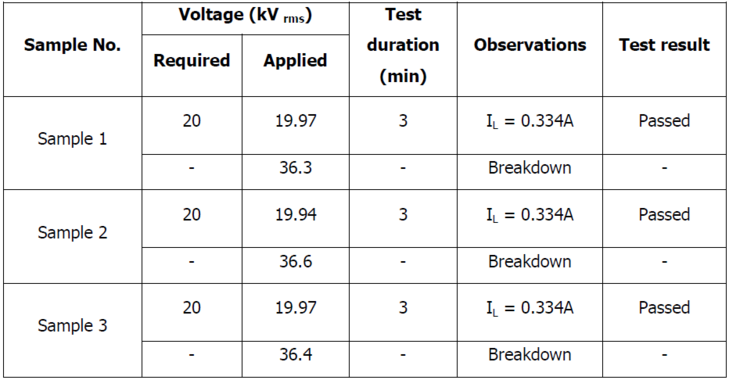

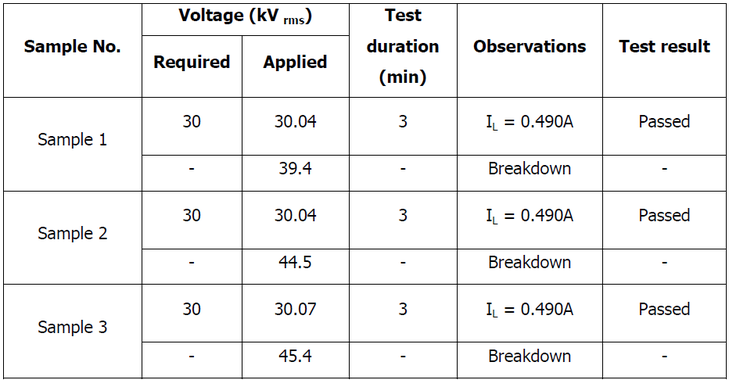

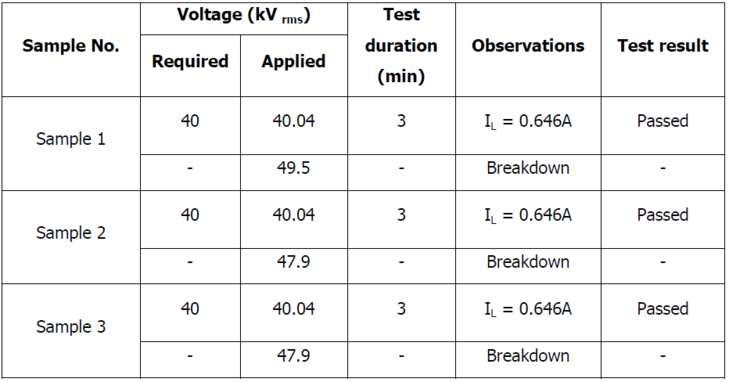

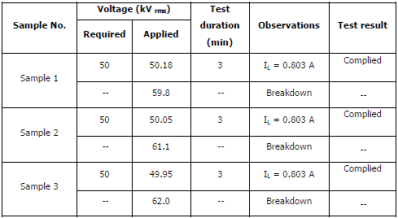

Our Switchboard matting / high voltage insulation rubber was tested according to technical specifications:

A) BS EN 61111 Clause 5.6.4.3, Voltage Withstand Test

B) Complied to RoHS I & II, On 4th June 2015, Commission Directive (EU) 2015/863 was published in the Official Journal of the European Union (OJEU) to include the phthalates ( BBP, DBP, DEHP and DIBP, these are used to soften PVC and Vinyl ) into ANNEX II of the RoHS Recast Directive.

The new law restricts each phthalate to no more than 0.1% ( mg/kg = ppm ; 0.1wt% = 1,000ppm ) in each homogeneous material of an electrical product.

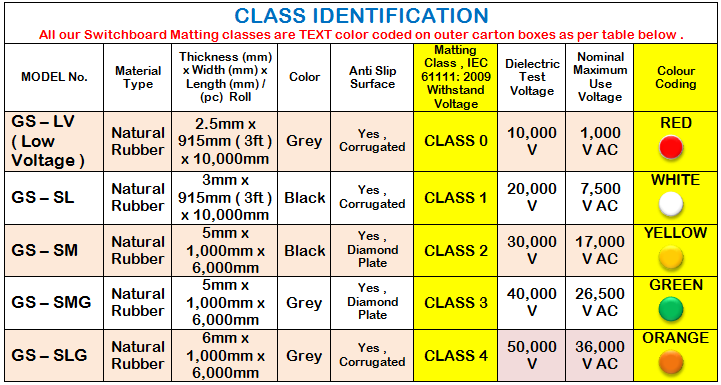

D) Product Characteristics:-

1) Material: RoHS-2 (Made Of Eco-friendly Raw Material - Complied to (EU) 2015/863 Directives)

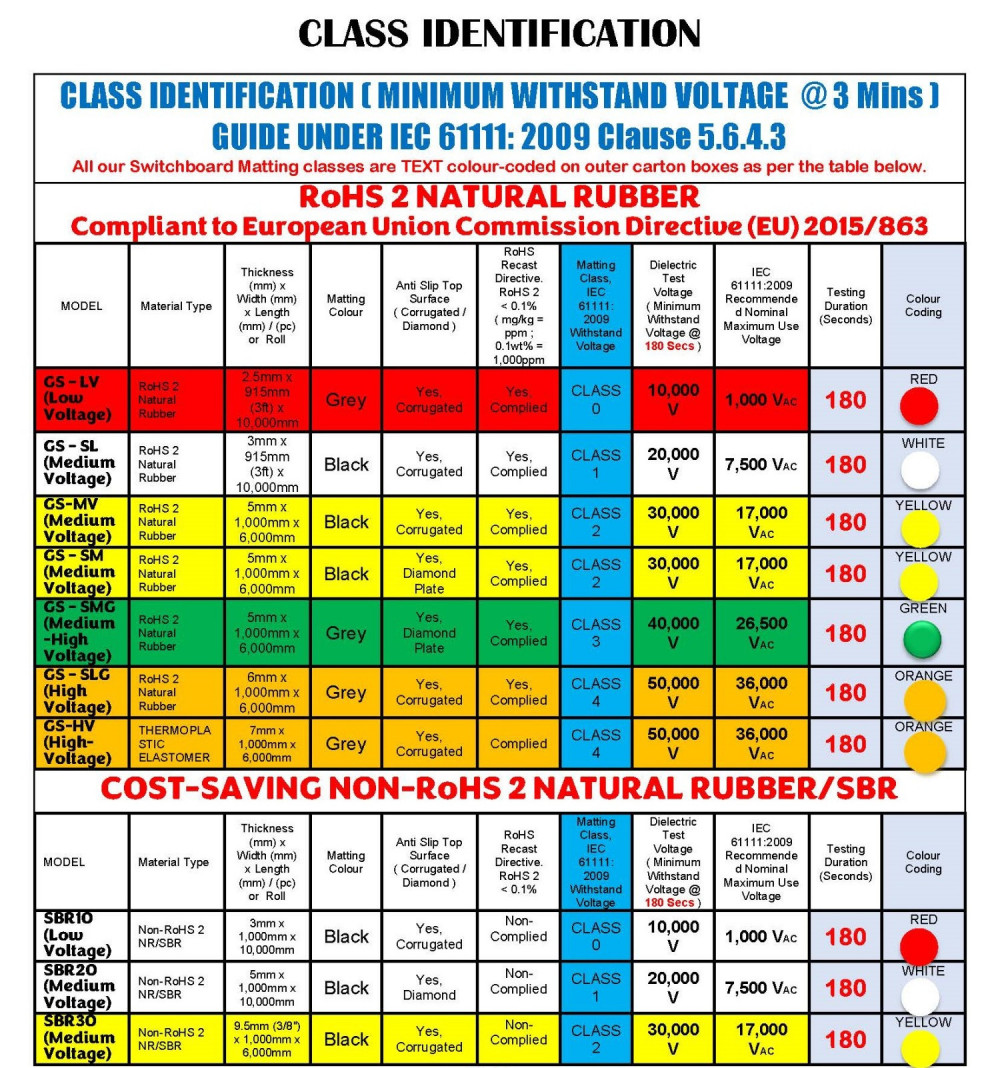

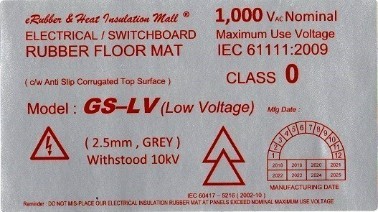

2) Model: GS-LV Low Voltage Switchboard Matting / High Voltage Insulation Rubber Mat -- with Anti Slip ( Corrugated ) on Top Surface, Withstood 10kV ( Class 0 ), 2.5mm Nominal Thickness, GREY Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 0 ) + SIRIM + SGS

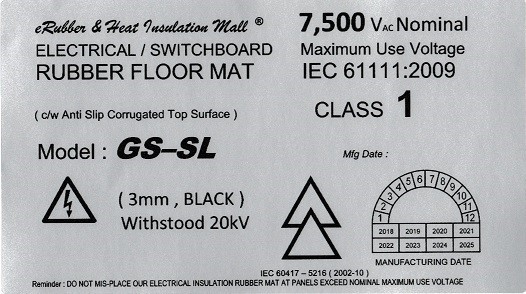

3) Model: GS-SL Switchboard Matting / High Voltage Insulation Rubber Mat -- with Anti Slip ( Corrugated ) on Top Surface, Withstood 20kV ( Class 1 ), 3mm Nominal Thickness, BLACK Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 1 ) + SIRIM + SGS

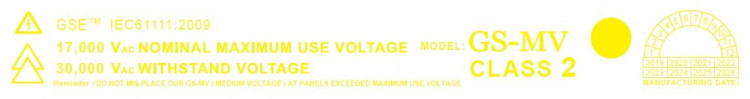

4) Model: GS-MV Switchboard Matting / Medium Voltage Insulation Rubber Mat -- with Anti Slip ( Corrugated ) on Top Surface, Withstood 30kV ( Class 2 ), 5mm Nominal Thickness, BLACK Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 2 ) + SIRIM + SGS

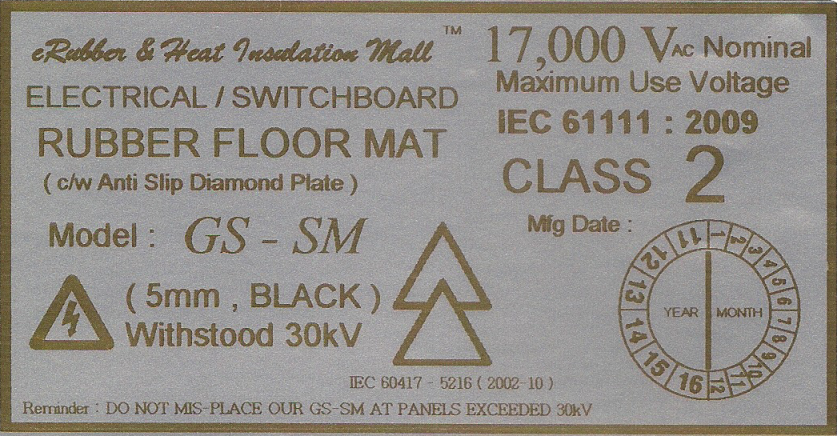

5) Model: GS-SM Switchboard Matting / Medium Voltage Insulation Rubber Mat -- with Anti Slip ( Diamond Plate ) on Top Surface, Withstood 30kV ( Class 2 ), 5mm Nominal Thickness, BLACK Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 2 ) + SGS

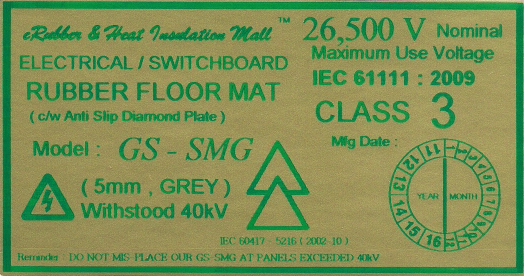

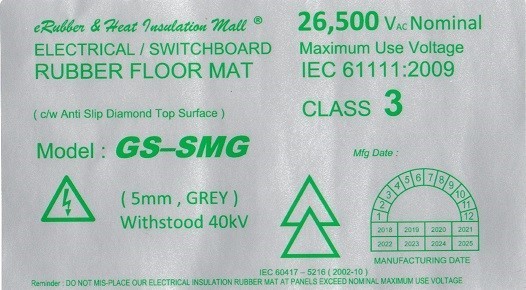

6) Model: GS-SMG Switchboard Matting / Medium High Voltage Insulation Rubber Mat -- with Anti Slip ( Diamond Plate ) on Top Surface, Withstood 40kV ( Class 3 ), 5mm Nominal Thickness, GREY Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 3 ) + SGS

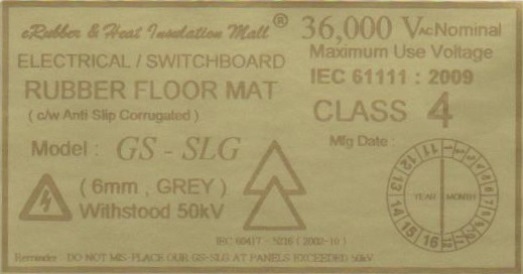

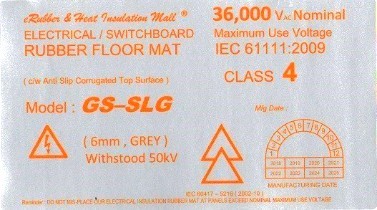

7) Model: GS-SLG High Voltage Insulation Rubber Mat -- with Anti Slip ( Corrugated ) on Top Surface, Withstood 50kV ( Class 4 ), 6mm Nominal Thickness, GREY Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 4 ) + SIRIM + SGS

8) Model: GS-HV High Voltage Insulation Thermoplastic Elastomer Mat -- with Anti Slip ( Corrugated ) on Top Surface, Withstood 50kV ( Class 4 ), 7mm Nominal Thickness, GREY Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 4 ) + SIRIM + SGS

Material: Non-RoHS-2 (COST-SAVING SBR GRADE)

9) COST-SAVING SBR GRADE:- (Non-RoHS 2)

A) Which product is the correct Electrical Insulating Matting for protection against electric shock risk?

BS EN 61111:2009 is the latest standard for electrical insulating matting in providing electrical protection.

B) International Withdrawal of BS921:1976?

This old standard is being withdrawn on 1st Jan 2013 ( Standard number, BS 921: 1976, Specification: Rubber mats for electrical purposes, status: WITHDRAWN ) as it conflicts with IEC61111:2009.

The direct Electrical Insulating Matting to replace BS921 is class 0 IEC 61111:2009 for working up to 1kV AC.

For higher voltage, you may select higher classes 1, 2, 3 or 4 according to the voltage resistance required.

C) Quality Assurance

Our Switchboard Mattings are backed with a detailed test certificate & RoHS compliant from an independently accredited Malaysia Test Facility.

Our Switchboard matting / high voltage insulation rubber was tested according to technical specifications:

A) BS EN 61111 Clause 5.6.4.3, Voltage Withstand Test

B) Complied to RoHS I & II, On 4th June 2015, Commission Directive (EU) 2015/863 was published in the Official Journal of the European Union (OJEU) to include the phthalates ( BBP, DBP, DEHP and DIBP, these are used to soften PVC and Vinyl ) into ANNEX II of the RoHS Recast Directive.

The new law restricts each phthalate to no more than 0.1% ( mg/kg = ppm ; 0.1wt% = 1,000ppm ) in each homogeneous material of an electrical product.

D) Product Characteristics:-

1) Material: RoHS-2 (Made Of Eco-friendly Raw Material - Complied to (EU) 2015/863 Directives)

2) Model: GS-LV Low Voltage Switchboard Matting / High Voltage Insulation Rubber Mat -- with Anti Slip ( Corrugated ) on Top Surface, Withstood 10kV ( Class 0 ), 2.5mm Nominal Thickness, GREY Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 0 ) + SIRIM + SGS

3) Model: GS-SL Switchboard Matting / High Voltage Insulation Rubber Mat -- with Anti Slip ( Corrugated ) on Top Surface, Withstood 20kV ( Class 1 ), 3mm Nominal Thickness, BLACK Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 1 ) + SIRIM + SGS

4) Model: GS-MV Switchboard Matting / Medium Voltage Insulation Rubber Mat -- with Anti Slip ( Corrugated ) on Top Surface, Withstood 30kV ( Class 2 ), 5mm Nominal Thickness, BLACK Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 2 ) + SIRIM + SGS

5) Model: GS-SM Switchboard Matting / Medium Voltage Insulation Rubber Mat -- with Anti Slip ( Diamond Plate ) on Top Surface, Withstood 30kV ( Class 2 ), 5mm Nominal Thickness, BLACK Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 2 ) + SGS

6) Model: GS-SMG Switchboard Matting / Medium High Voltage Insulation Rubber Mat -- with Anti Slip ( Diamond Plate ) on Top Surface, Withstood 40kV ( Class 3 ), 5mm Nominal Thickness, GREY Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 3 ) + SGS

7) Model: GS-SLG High Voltage Insulation Rubber Mat -- with Anti Slip ( Corrugated ) on Top Surface, Withstood 50kV ( Class 4 ), 6mm Nominal Thickness, GREY Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 4 ) + SIRIM + SGS

8) Model: GS-HV High Voltage Insulation Thermoplastic Elastomer Mat -- with Anti Slip ( Corrugated ) on Top Surface, Withstood 50kV ( Class 4 ), 7mm Nominal Thickness, GREY Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 4 ) + SIRIM + SGS

Material: Non-RoHS-2 (COST-SAVING SBR GRADE)

9) COST-SAVING SBR GRADE:- (Non-RoHS 2)

Model: SBR10 Low Voltage Switchboard Matting / High Voltage Insulation Rubber Mat -- with Anti Slip ( Corrugated ) on Top Surface, Withstood 10kV ( Class 0 ), 3mm Nominal Thickness, BLACK Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 0 )

10) COST-SAVING SBR GRADE:- (Non-RoHS 2)

Model: SBR20 Switchboard Matting / High Voltage Insulation Rubber Mat -- with Anti Slip ( Diamond ) on Top Surface, Withstood 20kV ( Class 1 ), 5mm Nominal Thickness, BLACK Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 1 )

11) COST-SAVING SBR GRADE:- (Non-RoHS 2)

Model: SBR30 Switchboard Matting / High Voltage Insulation Rubber Mat -- with Anti Slip ( Corrugated ) on Top Surface, Withstood 30kV ( Class 2 ), 9.5mm (3/8") Nominal Thickness, BLACK Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 2 )

12) Surface finishing: with anti-slip corrugated/diamond plate surface to provide a safe working environment

13) Scope , Usage & Application :-

High Voltage Insulation Rubber Mats / Non-Conductive Mats - Most commonly called Switchboard matting, these non-conductive mats protect workers from deadly shocks generated by high voltage equipment.

High Voltage Insulation Rubber mats are NORMALLY used as a floor covering electrical panels at Power Transformer Rooms, Sub-Station, High Voltage Panels, LT & HT Labs, Control Panels etc . it acts as a safety precaution for workers from electrical shock whether they are involved directly in electricity generation, transmission, distribution or another usage.

Eventually, the High Voltage Insulation Rubber Mats need to be tested ( with proven data from the LOCAL or an internationally accredited testing body ) before being placed in electrical generator rooms.

The carelessness of handling electrical apparatus or Mis-used of high voltage insulation rubber sheets/mats could be harmful to workers. For example, Matting Class 0 ( 10kV ) or Class 1 ( 20 kV ) High Voltage Insulation Rubber Mats placed at Class 2, 30 kV working environment of electrical generator rooms.

Choosing the correct High Voltage Insulation Rubber Mat / Sheet is extremely IMPORTANT; these mats save money and lives because human life is above everything. We strongly recommend our customers use one class higher than the nominal working voltage environment to secure the safety of workers. Our goal is to assist in achieving " ZERO " industrial accidents resulting from voltage leakage.

Life span :

The Life span of The Switchboard Rubber Mats very much depends on Rubber Compound Itself and external environmental factors such as:-

1) Foot traffic, high foot traffic reduces the rubber’s life span.

2) Environments include exposure to oils, moisture, caustic chemicals or fluids, and prolonged exposure to high temperatures ( direct exposure to sunlight ).

3) Cleaning Method: No harmful/corrosive detergents.

Know-How :

When to change my Switchboard Rubber Mats?

1) Our recommendation is to CHANGE IT when you find your rubber mats become "hardened due to ageing" and crack ( puncture ). (AFTER INSTALLATION)

(Electrical Professionals highly recommend that electrical insulation rubber mat be replaced every 12 months of usage for optimum performance).

Electrical Insulation Rubber matting is not permanent and needs to be replaced periodically & consistently.

10) COST-SAVING SBR GRADE:- (Non-RoHS 2)

Model: SBR20 Switchboard Matting / High Voltage Insulation Rubber Mat -- with Anti Slip ( Diamond ) on Top Surface, Withstood 20kV ( Class 1 ), 5mm Nominal Thickness, BLACK Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 1 )

11) COST-SAVING SBR GRADE:- (Non-RoHS 2)

Model: SBR30 Switchboard Matting / High Voltage Insulation Rubber Mat -- with Anti Slip ( Corrugated ) on Top Surface, Withstood 30kV ( Class 2 ), 9.5mm (3/8") Nominal Thickness, BLACK Colour with TNB Test Certificate : ( BS EN 61111: 2009 Clause 5.6.4.3 Class 2 )

12) Surface finishing: with anti-slip corrugated/diamond plate surface to provide a safe working environment

13) Scope , Usage & Application :-

High Voltage Insulation Rubber Mats / Non-Conductive Mats - Most commonly called Switchboard matting, these non-conductive mats protect workers from deadly shocks generated by high voltage equipment.

High Voltage Insulation Rubber mats are NORMALLY used as a floor covering electrical panels at Power Transformer Rooms, Sub-Station, High Voltage Panels, LT & HT Labs, Control Panels etc . it acts as a safety precaution for workers from electrical shock whether they are involved directly in electricity generation, transmission, distribution or another usage.

Eventually, the High Voltage Insulation Rubber Mats need to be tested ( with proven data from the LOCAL or an internationally accredited testing body ) before being placed in electrical generator rooms.

The carelessness of handling electrical apparatus or Mis-used of high voltage insulation rubber sheets/mats could be harmful to workers. For example, Matting Class 0 ( 10kV ) or Class 1 ( 20 kV ) High Voltage Insulation Rubber Mats placed at Class 2, 30 kV working environment of electrical generator rooms.

Choosing the correct High Voltage Insulation Rubber Mat / Sheet is extremely IMPORTANT; these mats save money and lives because human life is above everything. We strongly recommend our customers use one class higher than the nominal working voltage environment to secure the safety of workers. Our goal is to assist in achieving " ZERO " industrial accidents resulting from voltage leakage.

Life span :

The Life span of The Switchboard Rubber Mats very much depends on Rubber Compound Itself and external environmental factors such as:-

1) Foot traffic, high foot traffic reduces the rubber’s life span.

2) Environments include exposure to oils, moisture, caustic chemicals or fluids, and prolonged exposure to high temperatures ( direct exposure to sunlight ).

3) Cleaning Method: No harmful/corrosive detergents.

Know-How :

When to change my Switchboard Rubber Mats?

1) Our recommendation is to CHANGE IT when you find your rubber mats become "hardened due to ageing" and crack ( puncture ). (AFTER INSTALLATION)

(Electrical Professionals highly recommend that electrical insulation rubber mat be replaced every 12 months of usage for optimum performance).

Electrical Insulation Rubber matting is not permanent and needs to be replaced periodically & consistently.

OUTER CARTON BOX LABEL INDICATION :

SCAN OUR QR CODE CATALOGUE

Disclaimer :

* Note: Users need to evaluate suitability for their industry's use ( applications ) before placing an order from us.

The Information provided on this website best advises our customers to correspond to current electrical matting standards.

In the individual case, it is the customer's sole responsibility to evaluate requirements, mainly if specified properties are sufficient for use.